A 2019 Restoration Case Study

Since the early days of the Society, guidance notes have been provided to share good practice and encourage others to use the appropriate materials and processes in refurbishing milestones. Rarely however have we had the opportunity to record the casting of a large milepost from scratch, since the efforts of the Staffordshire group some years ago.

The foundry of Brayshaw & Booth at Liversedge in West Yorkshire cast some 620 mileposts at the request of the new West Riding County Council in the 1890s. These were to be “six inches thick, with iron plates, bolted, showing the name of the road, township and mileage to nearest towns”. The stone was to come from the Horsforth Quarries and the milestones were to be 6 feet high, set two feet into the ground. The estimated cost would be £2-5-0d each. The contract was awarded to G & F Stead, stonemasons in Mirfield (Gill Stead and his son Frank), who erected 619 stones within 12 months, a prodigious achievement. Over half of these milestones still survive in place, apparently not having been removed or defaced in WWll.

One such was opposite the Wappy Springs Inn, at Outlane, near Huddersfield. (Fig 1) Passing the site in late 2018, Jan Scrine noticed that the milepost and the wall against which it had stood were gone – replaced by the entrance to a new industrial development. Enquiries were made to Kirklees Council, helpfully corroborated by Stan Driver, the former Senior Conservation Officer at the Council, who dug out the site’s planning applications. These indicated the presence of the milepost. Other Society members had mentioned it to the contractors in passing, but apparently the milepost had vanished.

Taking the Society’s own published advice, the local Councillors were contacted and their follow-up supported the efforts of the Senior Highways Design Engineer, who took a real interest in the project. The developers agreed to fund a replica milepost and Stan Driver supplied extremely detailed guidance on size and composition. This was based on a similar milepost nearby, as well as his experience of replacing a series of Brayshaw & Booth mileposts in 2004.

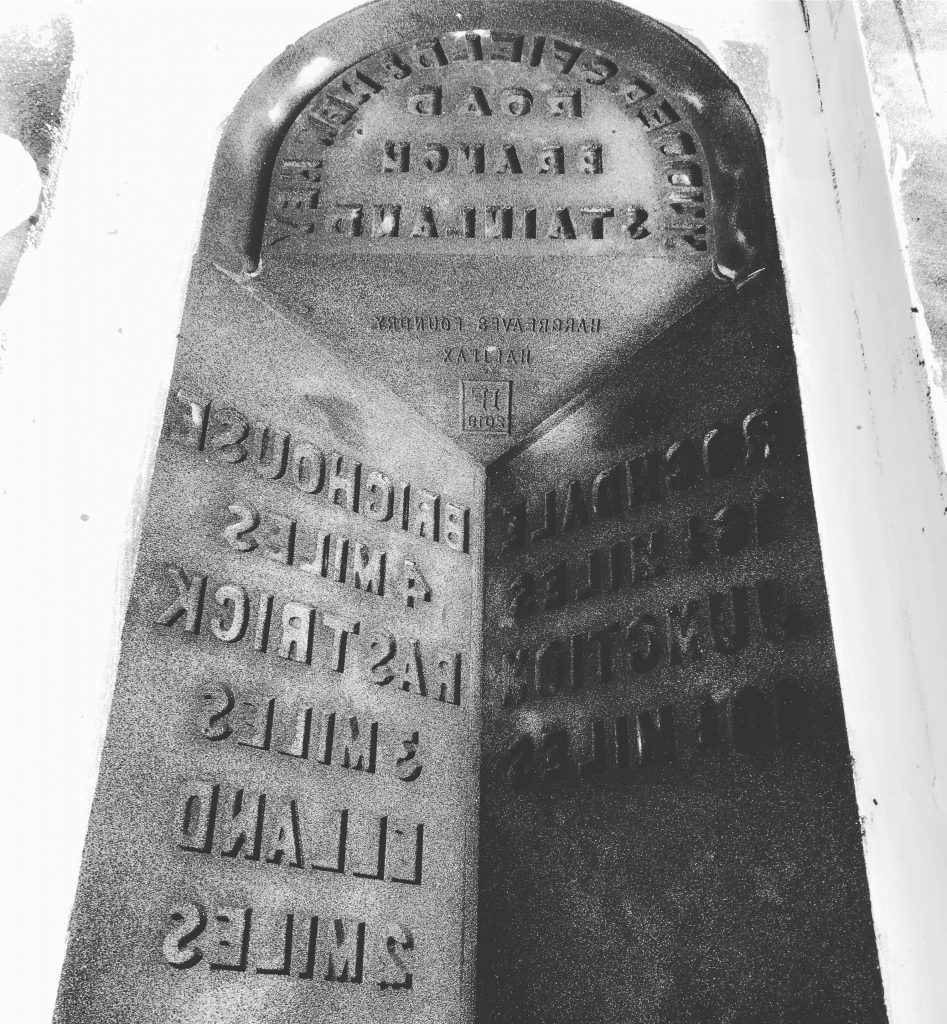

Hargreaves Foundry in Halifax was tasked with the job. They prepared a wooden pattern (fig 2) and from this a mould (fig 3) made of Furan Resin Sand which came from China. This is a kind of self-hardening sand; after the coating is burned, the surface of the sand mould becomes extremely hard. A model was prepared (fig 4) then the final cast was made and painted (fig 5). The white coating was sprayed on using an AE52 paint system, a two pack polyurethane finish designed to have excellent durability and abrasion resistance – the technical instructions state that ‘Substrates must be thoroughly cleaned, dry and free from contaminants, corrosion and grease prior to coating’. The black lettering was AE53, ‘A high solids Polyurethane Compliant Finish for general purpose use with good salt spray resistance’, applied by roller. The casting bears the name of the foundry and the date 2019.

The cost of the casting project was £4160 including VAT; the developers are to be congratulated for their willingness to expend this amount to restore the milepost. Thanks are also due to the highways engineers, councillors and local Milestone Society members for their good-humoured persistence in following the matter to its happy conclusion.

A backing stone has been obtained and in March 2021 the milepost was installed near to its original location by the Kirklees Highways team, (Figs 6 & 7) - a job well done!

Geograph Ref: 6775467 ; Milestone Society National ID: YW_BHOU04R

And the Brayshaw & Booth mould will also be available for any such future projects…